Achieved a Fast Start-up of Production Lines

Nakamura Electric Industry Co., Ltd.

Automotive Parts Industry

- Challenge of Producing In-house

- Automotive Parts

- Improving Production Line Efficiency

- Factory IoT

- Improvement

Ennovie

Jewelry Industry

Ennovie, a jewelry manufacturer in Thailand, was faced with the difficulty of automation, despite rapidly increasing demand. The challenge was how to increase efficiency while preserving the craftsmanship that had been cultivated in jewelry production. That is why they started innovating.

Going back to the basics of the production site, we analyzed the actual state of production in detail using IoT technology based on the principles of lean production. The combination of kaizen and step-by-step automation has produced remarkable results. Production efficiency increased significantly from 16% to 65%. Ennovie's challenge is expanding new possibilities in jewelry manufacturing.

Our company manufactures high quality jewelry for leading brands worldwide. We offer a wide range of products while keeping sustainability and lean production as core values. While we had already successfully mechanized 80% of our production, automating the remaining manual work was a challenging task. Faced with a rapid increase in demand, we had to choose between increasing manpower and improving efficiency.

Efforts to improve efficiency proceeded step by step. First, a profit-sharing program was introduced to improve motivation. Next, we analyzed each process in detail and began implementing systematic improvement methods. We considered automating all processes, but found that it would be difficult to apply in the jewelry industry.

So, we decided to change our way of thinking and return to the basic principles of lean production. By utilizing IoT technology to collect accurate data and identify key issues, we found a path to developing a step-by-step automation plan and implementing effective improvement activities.

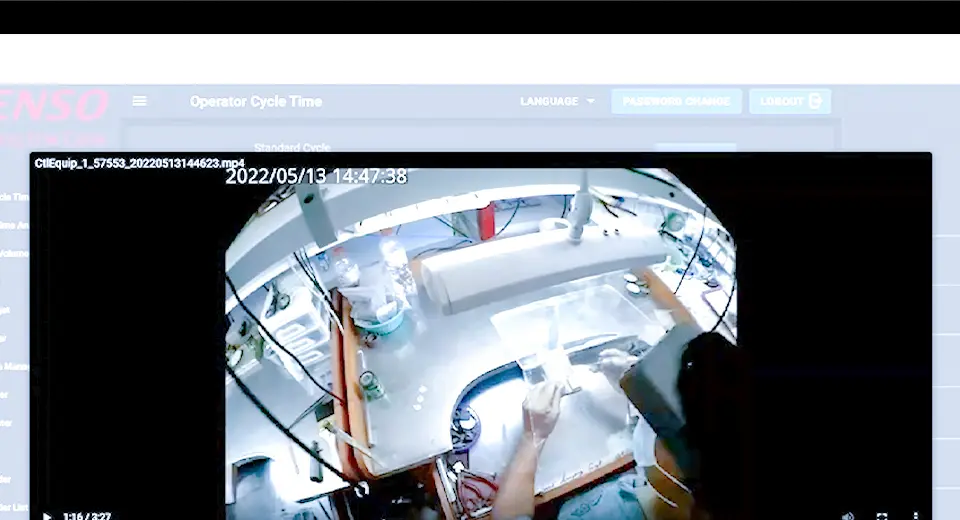

During the project with DENSO, we conducted 3 times of kaizen. As a result, we were greatly shocked by the fact that the current efficiency was lower than expected, which made us realize that we needed to establish a calculation standard to benchmark performance. This allowed us to identify the main losses in the production lines and prioritize actions for improvement.

An important factor in improving efficiency was the technology for analyzing elemental work developed in the automotive industry.This technology revealed specific problems with work consistency. Based on the results of this analysis, managers can now provide effective feedback to operators.

In addition, we have established a new daily routine utilizing morning meetings. Top management and operators have an opportunity to reflect on the video together. Through this effort, top management informs all operators of the importance of consistency in their work and promotes better self-awareness.

It helps spread the understanding among operators that quality and consistent work leads to an increase in their own income through the profit-sharing program. This system creates a positive cycle that benefits all of them: employees, management, and the company.

As a result of the kaizen, efficiency increased from 16% to 65%. We have reduced management loss, start-up loss, and inventory loss. However, our efforts have only just begun. We are aiming to further improve efficiency by rolling out this improvement model to all production lines.

Now that we have a better understanding of the manufacturing process, our new goal is to automate approximately 70% of the process. We plan to thoroughly analyze each step of the process and make systematic improvements, and we are confident that this gradual automation and continuous improvement effort will open up new possibilities for jewelry manufacturing.

Our challenge to establish innovative production methods by integrating traditional craftsmanship and cutting-edge technology has only just begun. We will continue to pursue new possibilities in jewelry manufacturing through continuous improvement and innovation.

We will lay the foundation for maximizing productivity and improving your manufacturing site with advice based on our skills and experience. Please feel free to contact us for more information.

The Future of Factories Begins Here.