Achieved a Fast Start-up of Production Lines

Nakamura Electric Industry Co., Ltd.

Automotive Parts Industry

- Challenge of Producing In-house

- Automotive Parts

- Improving Production Line Efficiency

- Factory IoT

- Improvement

Sriborisuth Forging Technology Co., Ltd.

Automotive Parts Industry

Sriborisuth Forging Technology Co., Ltd. is an automotive parts manufacturer established in 2010. The company was facing issues such as uneven workload, lack of accuracy in demand forecasting and complex flow lines at its automotive parts manufacturing site, where human resource shortages and productivity improvement are critical issues.

To address these issues, a solution based on DENSO's Lean Automation was introduced. The automation by robots has produced remarkable results in terms of productivity improvement and work loss reduction. The following is a detailed introduction of their efforts.

We specialize in hot forging of metals and had been facing various issues such as decreased efficiency due to fluctuations in the workload for each process, excessive inventory due to inaccurate demand forecasting, and complex workflow lines due to wasteful worker moves and operations. To improve productivity over the long term, we sent our engineers to DENSO's Lean Automation System Integrator (LASI), where they acquired Lean Automation know-how and successfully implemented automation on our factory.

As a result, we have achieved significant improvements, such as a 30% increase in productivity through robot automation, a cycle time of 2.5 seconds/piece, and OEE of 85% by reducing work loss through high-speed forging die changeover. We also reduced the number of production line workers by 3 per line. In addition, by having robots do heavy labor and complex tasks, the workload on workers is reduced.

We are very satisfied with the results of this automation by Lean Automation and are considering expanding it to other forging lines in the future.

Participating in DENSO's LASI program and learning the know-how of Lean Automation was a turning point for us.

In particular, the words of LASI instructor Fumio Kojima made us realize something important: “If automation does not improve productivity, it is meaningless. We must improve productivity to make the investment worthwhile.”

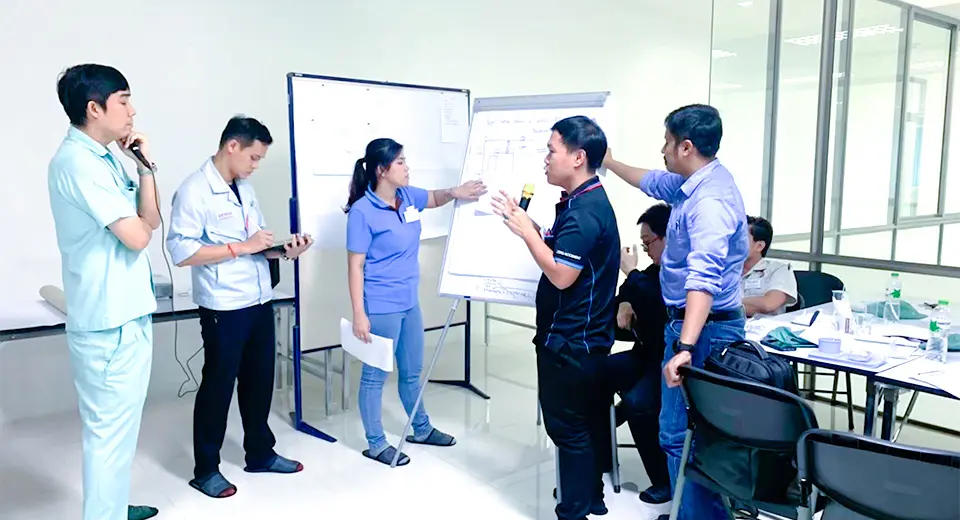

To realize truly effective automation and improve productivity, it was important for the on-site production engineers to be actively involved and to cooperate and communicate with the SIer (System Integrator), making final adjustments while sharing issues, improvements and knowledge each other. The key to success was that everyone involved, including stakeholders, shared the common philosophy of “Lean” and were able to build a cooperative relationship.

This is how we achieved automation and kaizen through Lean Automation.

We will lay the foundation for maximizing productivity and improving your manufacturing site with advice based on our skills and experience. Please feel free to contact us for more information.

The Future of Factories Begins Here.